CAD/CAM

Apelt has been working with Edgecam, the new production solution, since 2015. This CAD/CAM system enables a finished product to be created directly from a 3D model.

With Edgecam, the modern, high-performance CAD/CAM system, even the most complex of parts can be produced quickly and reliably. The system features highly capable modules for the following types of machining:

An overview of the Edgecam modules

Production milling/An overview of milling

The Edgecam range of machining options extends from 2.5D to complex 3D and on to 5-axis simultaneous machining. It offers all the settings that the advanced user might require.

3D milling

Edgecam 3D milling is the complete solution for the creation of high-quality, collision-free tool paths for the machining of complex free-form surfaces and for programming. It provides the best machining strategies for cubic parts as well as powerful functions for machining free 3D volume and surface models (e.g. production strategies for the turning and milling of shaft shapes).

4 and 5-axis machining

With Edgecam, 4/5-axis simultaneous machining can be integrated in the milling as well as in the turning/milling environment. This provides a great many strategies for complex machining tasks and for the multi-axis milling of components. All sectors of production worldwide now employ 4/5-axis machining. As a result, high-tech machines have now become affordable, and yet more complex shapes also require yet more complex tool paths.

Turning/Milling

With the Edgecam turning/milling module, programming in the complex work spaces of modern machine tools has become simpler and safer.

Turning

All axis configurations can be supported by Edgecam. This includes simple 2-axis turning machines, multi-spindle configurations as well as CAB double-spindle machines with a counter-spindle.

Workflow

With the ‘Workflow’ Edgecam module, production costs are lowered, the quality of produced components is improved and machining times are reduced.

Strategy Manager

The Edgecam ‘Strategy Manager’ provides the best possible combination of rules, expertise and feature-based machining. This can facilitate a fast, highly automated and safe solution for the NC programming of parts.

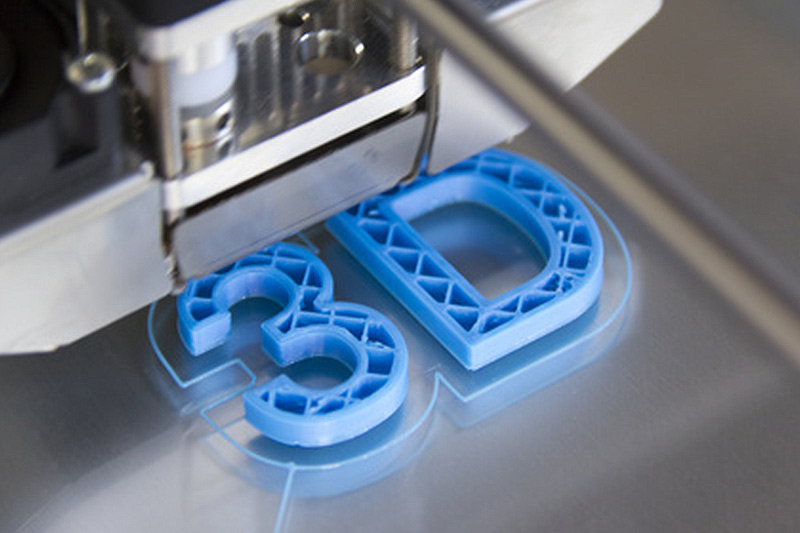

3D printing at Apelt

At Apelt, it is important to keep up with the latest technologies.

This is why we have invested in a 3D printer, because precision begins long before chip-cutting in production. We not only wish to use this new device for additive production. Instead, we wish to backstop what we have already achieved, as well as to visit pastures new.

For example, the new 3D printer will be used to support our prototyping activities, e.g. :

- to backstop quotations for complex components

- as an aid to better spatial presentation when programming

- to produce measuring programs before production starts

- as the basis for our inspection strategy, running tests alongside production

- to produce assembly fixtures and clamping equipment for fragile components

In addition, this 3D printer should support ongoing production. Here are some examples of what that covers:

- Manufacture of specialist catching equipment to enable parts to be unloaded from machines without damage

- Production of special attachments for blast air or KS connections for tools

- Manufacture of protective special packaging to customer specification

You are most welcome to order these services from us with immediate effect.